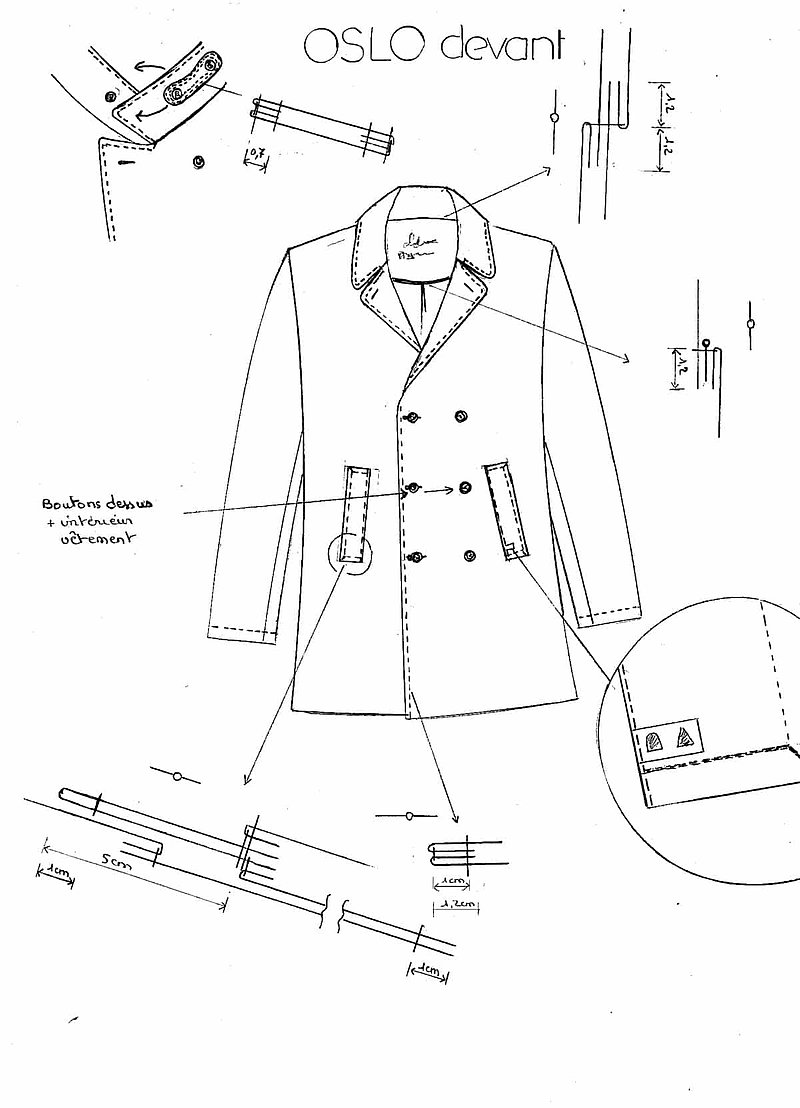

1 The design of a peacoat model

The models, materials and finishes of our peacoats are imagined and designed by our crew in our offices in Paimpol, Brittany.

2 Prototyping

Studied in detail to guarantee solidity and functionality, our prototype peacoats are tested for sale in our stores in the port of Paimpol.

3 The choice of materials

We pay a lot of attention to the choice of buttons, linings and all those little details that make our peacoats unique.

We are committed to favouring the use of French raw materials, respectful of the environment, human health and animal well-being.

To design our real peacoat, we use French woollen cloth, a warm, hard-wearing, breathable and water-repellent fabric. Our historical supplier is based in the Tarn, an exceptional French company, certified “Entreprise du Patrimoine Vivant”.

The stages in the manufacture of French woollen cloth

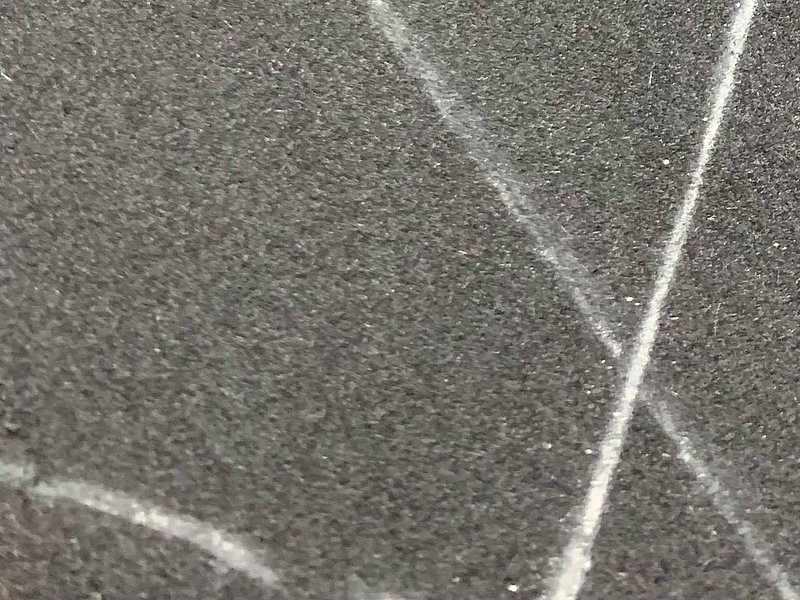

4 Marking

Every detail of the peacoat is marked on the French wool sheet we use to ensure a perfect fit.

5 Cutting and placement

Once the marking is complete, each part of the peacoat is carefully cut in one of our partner production units.

All the pieces of the peacoat are then joined together to form the finished product.

6 Assembling

100% of our peacoats are made in Europe. We decide, depending on the season, the availability of factories, the volume and the models, to produce our peacoats in a one of our partner units.

The workshops that we work with are selected according to their know-how and their availability. The quality result is identical from one model to another.

8 Quality Control

Every detail of each peacoat is rigorously checked at several levels of the chain throughout the manufacturing process.

Our crew carries out the last check in Paimpol before offering our peacoats for sale.

9 The distribution

Dalmard Marine peacoats are available in our stores in the port of Paimpol, in our partner sales outlets and on the Internet.

10 The usage of the peacoat

By repairing small snags and giving maintenance advice to our customers, we increase the life span of the peacoat and and reduce their carbon impact. If a Dalmard Marine peacoat is worn for 10 years, it emits between 10 and 15kg of CO2/year. If it is worn for 25 years, it emits 4 to 6kg of CO2/year.